Gain new perspectives for faster progress directly to your inbox.

Semiconductors are integral to our society and essential to the functioning of technology we rely on daily. But, as the electronics industry moves toward creating a more sustainable future, consumers and businesses alike have begun asking questions about the semiconductor lifecycle and how we can create more circularity.

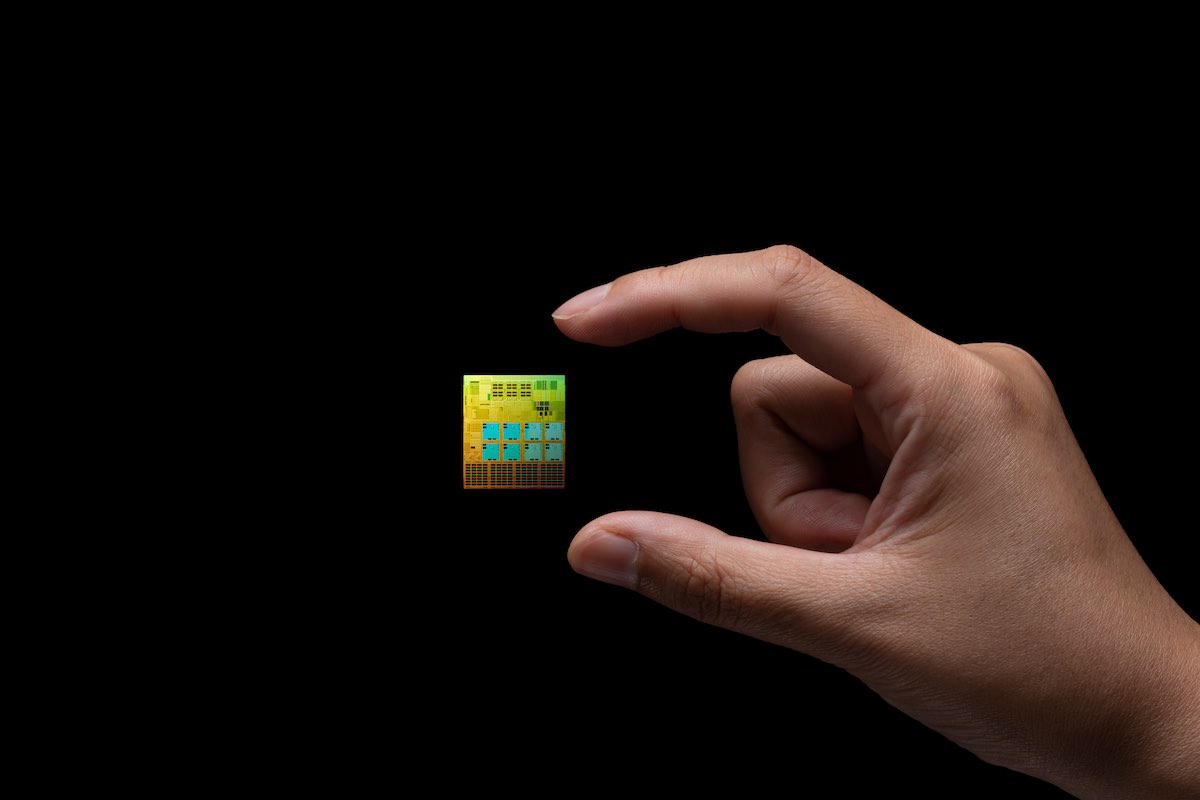

If we consider the complexity of the recycling methods needed to recycle mixed plastics, then we begin to realize the monumental task of designing technology to recycle semiconductors. Made of a mix of materials, from plastic to metal alloys and containing hazardous chemicals, each part of the semiconductor has different recycling needs, requiring an intricate infrastructure of several recycling streams to achieve full circularity. So how, then, do we begin to tackle this gargantuan challenge? And what opportunities for growth and innovation are beginning to emerge in this industry?

Designing with recycling in mind

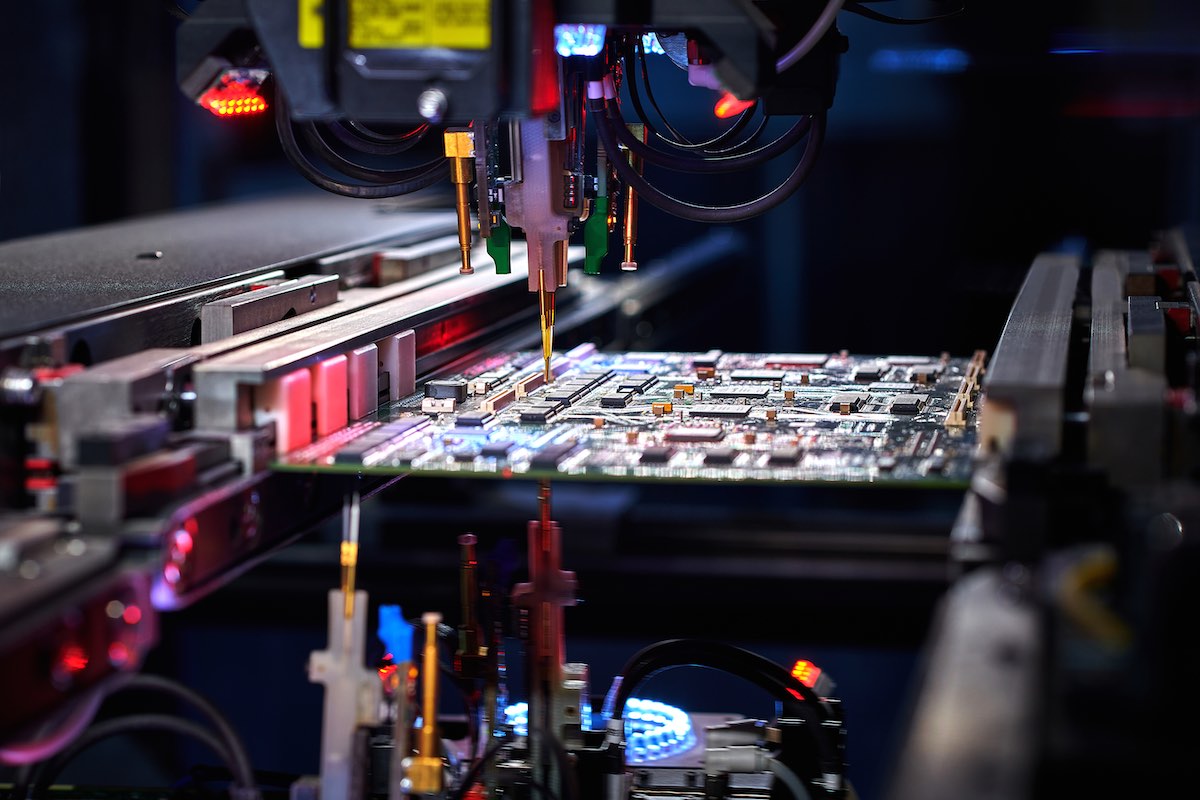

The key first step to improving the chances of recycling a semiconductor at the end of its life is foresight during the design and manufacturing phases. It is the responsibility of the researchers developing and producing semiconductors to do so with the product lifecycle and recycling potential in mind. From using novel materials to reducing the harmful chemicals involved, manufacturers can create semiconductors that are easier, cheaper, and safer to recycle, setting the industry up for sustainability success.

One way researchers have been designing for the ability to recycle semiconductors in the future is by introducing sustainable or non-toxic alternatives to semiconductor components like chitosan-based photoresists and non-toxic water-based developers. While these greener options are not yet able to compete with their traditionally designed counterparts, they offer an exciting opportunity for future novel patents and designs.

Developing infrastructure for recycling semiconductors

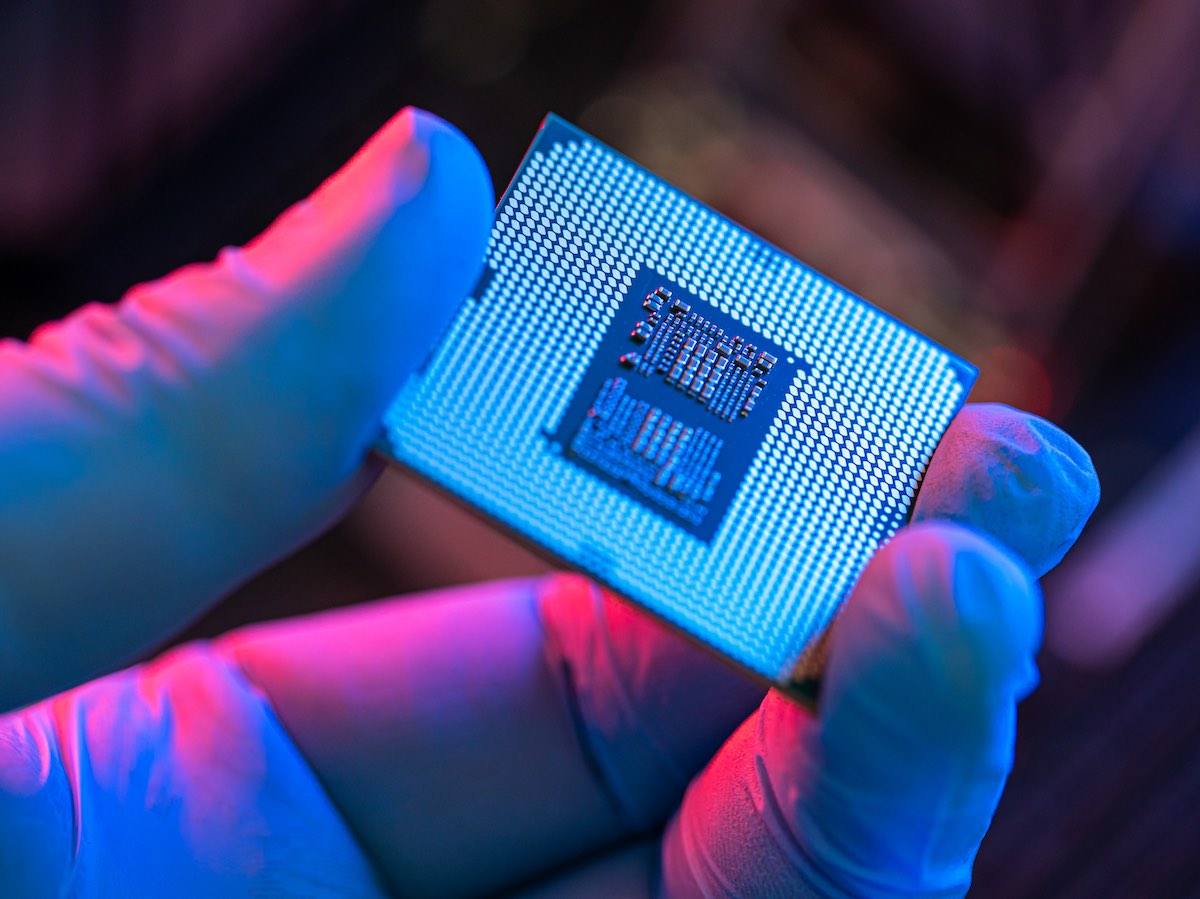

Beyond designing semiconductors with the end of the lifecycle in mind, researchers also need to design the end of the life cycle. Recycling semiconductors is not yet an established practice leaving huge scope for creativity and innovation to emerge and become the norm. As regulations around the globe, such as the European Chips Act, begin to focus on enforcing semiconductor sustainability and encouraging recycling, the industry must move quickly to create the infrastructure necessary to meet these requirements.

There are two approaches that are important here. Firstly, the industry will need to create new and sustainable technologies and practices for extracting and recycling semiconductors. Current processes are often energy-intensive, polluting, and linked to exploitative labor practices.

Secondly, to encourage the widespread adoption of any new recycling technologies, infrastructure would need to be put into place to collect used semiconductors and bring them to locations where they could be recycled. For semiconductor manufacturers, this is an opportunity to introduce circularity within their own products with buy-back or collection schemes that allow them to recover materials from their old semiconductors for use in their new ones.

So, what are companies doing right now?

Companies in the sector are currently focusing on introducing sustainable practices to their semiconductor manufacturing wherever possible. From Samsung’s recycled semiconductor trays to Infineon’s plans to reduce its greenhouse gas emissions by 70 percent by 2025, industry giants are bringing about a green revolution and setting themselves rigorous targets for improving semiconductor sustainability.

While recycling semiconductors remains on the back burner at the consumer end right now, it is at the cutting edge of industry research. Semiconductor manufacturers are going to need recycling innovations to appeal to eco-conscious consumers and comply with ever-tightening global regulations—and they’re going to need them soon.

Is semiconductor circularity within our grasp?

While a future of recycled semiconductors can feel out of reach, with the rate of advancements in recycling technologies and electronics design in recent years, researchers are likely to be quick off the mark with innovations for semiconductors. Consumer demand for eco-conscious products and global regulations around electronics sustainability will add momentum to drive the research forward. Manufacturers should make sure they are looking to this future and investing in research for recycling semiconductors or risk getting left behind. Learn more about related insights like new breakthroughs in lithium-ion battery recycling, why photocatalysis could unlock clean hydrogen, and new opportunities for nanocarbon tubes.